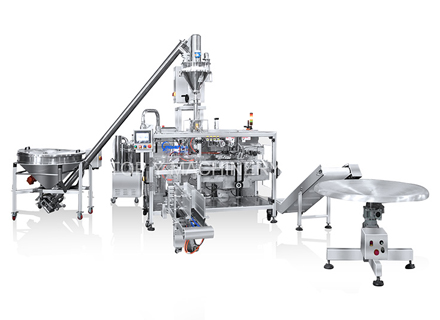

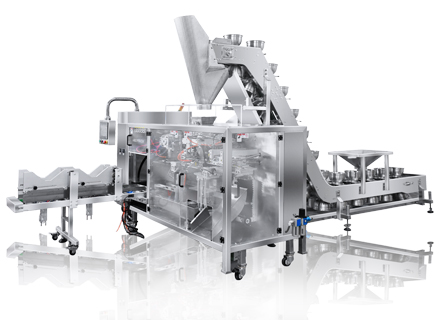

Fully Customized Design

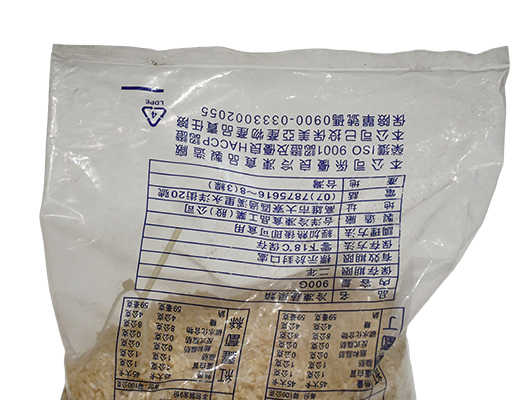

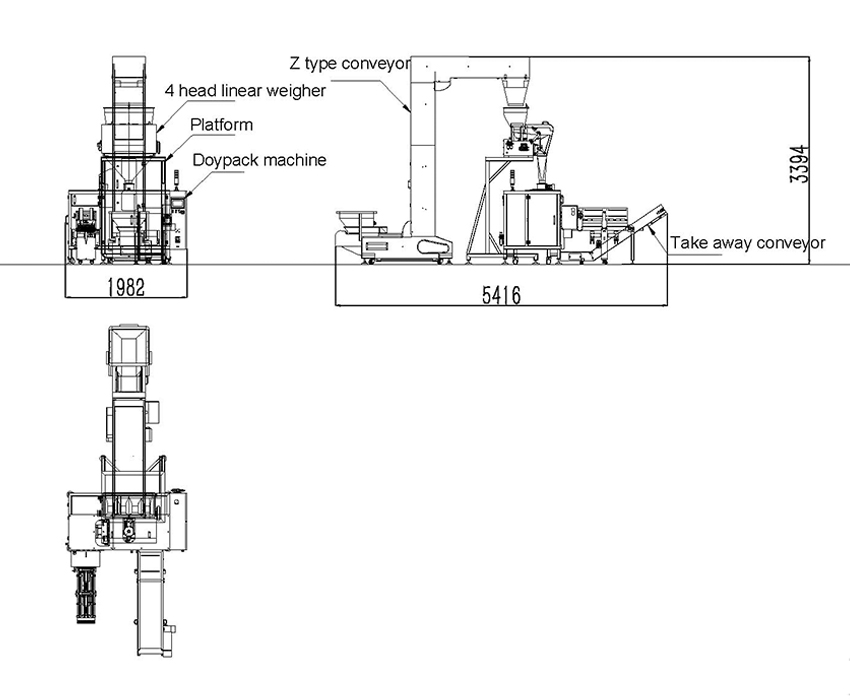

Each custom packaging machine is designed according to your product, bag type and production line.

Each custom packaging machine is designed according to your product, bag type and production line.

From semi-automatic to fully automatic packaging systems.

Industrial-grade structure ensures long-term stable operation.

We are able to customize the machine configuration according to different sealing requirements and packaging materials, ensuring reliable sealing performance and consistent package quality. Our available sealing solutions include, but are not limited to: