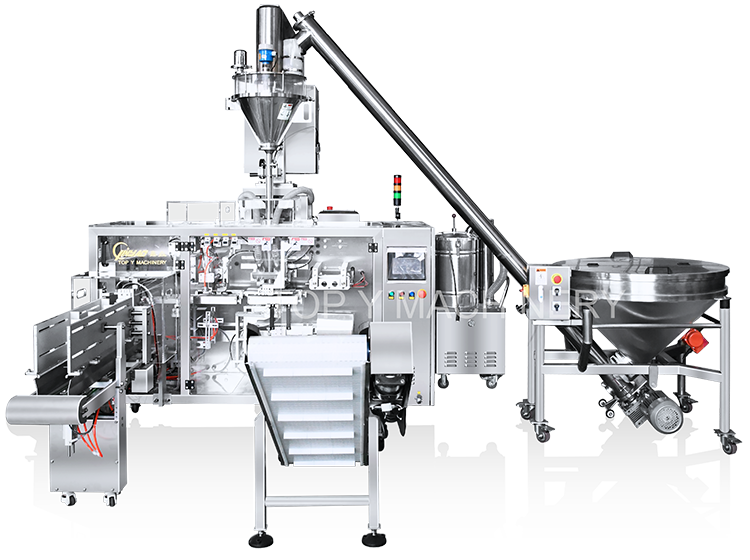

As a leading food packaging machine manufacturer, TOP Y has accumulated deep technical expertise in flexible pouch packaging for granules, powders, liquids, and various other materials. Our food packaging equipment is renowned worldwide for its stable performance, exceptional operational efficiency, and outstanding reliability, consistently earning high praise from clients across the globe.

We have achieved significant technological breakthroughs, especially in automated powder packaging and M-gusset bag applications. Through our proprietary innovations—such as advanced dust-suppression systems, drip-proof technology, anti-clumping mechanisms, high-precision dosing, and intelligent control systems—we have effectively resolved key industry challenges in traditional powder packaging, including heavy dependence on manual labor, severe dust pollution, inaccurate filling, and low productivity.

Our cutting-edge food packaging equipment enables fully automated production lines—from raw material feeding to final sealing—greatly enhancing production efficiency, improving workplace safety and hygiene, and providing the food industry with more reliable, efficient, and sustainable packaging solutions.