What are Auger Powder Food Packaging Machines: Features, Benefits, and Uses Explained

In the world of packaging, especially for powdered food products, precision, efficiency, and hygiene are paramount. We rely on advanced solutions to ensure product quality and operational seamlessness. The right machinery not only preserves the integrity of the product but also defines the productivity and profitability of the entire production line.

Today, we're diving into the specifics of Auger Powder Food Packaging Machines – understanding what they are, the unique characteristics that make them essential, and how they benefit various sectors within the food industry. From flour and spices to protein powders and instant coffee, these machines are the unsung heroes behind many of our daily staples.

Unpacking the Auger Powder Food Packaging Machine: What is it?

An auger powder food packaging machine is a specialized piece of equipment designed to dispense precise quantities of powders and granular products into various types of containers, such as bags, pouches, jars, or bottles. Its name comes from its core component: the auger, a spiral-shaped screw that rotates to move and measure the product. These machines are indispensable in the food industry for their ability to handle a wide spectrum of powders, from fine, non-free-flowing types like flour to more granular, free-flowing ones like sugar.

Defining the Auger Mechanism in Powder Food Packaging

The heart of the machine is the auger, a helical screw that is housed inside a tube or funnel. When the machine is in operation, product is fed from a storage container, called a hopper, into the tooling. The key components involved in the filling process are:

- The Hopper: This is the large conical container at the top of the machine that holds the bulk powder before it is dispensed. Its design ensures a consistent flow of material to the auger.

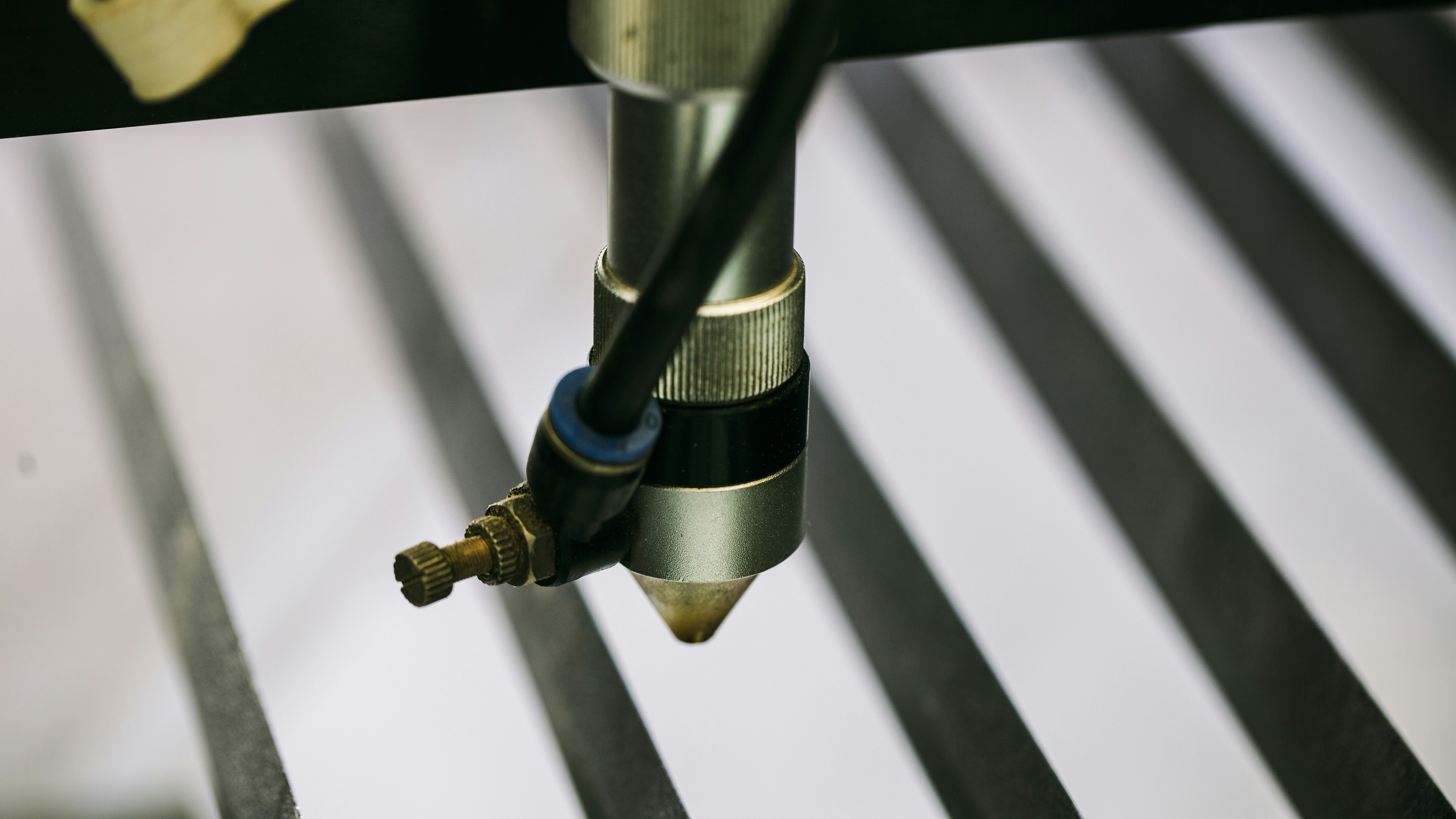

- The Auger Screw: This rotating, drill-like tool is the star of the show. It draws material down from the hopper and moves it towards the discharge point. The design of the auger—its diameter, pitch (the distance between the screw flights), and length—directly impacts the volume of product dispensed with each rotation.

- The Agitator: Many auger fillers include an agitator, which is a blade that rotates independently and in the opposite direction of the auger. Its purpose is to break up any clumps, prevent powder from bridging or "rat-holing" (a condition where powder sticks to the sides of the hopper), and ensure a consistent density of powder is fed into the auger flights. This is crucial for maintaining accuracy.

- The Funnel/Tube: This component guides the powder from the auger cleanly into the awaiting package, minimizing dust and product loss.

The Fundamental Principle Behind Every Auger Powder Food Packaging Machine

The fundamental principle of an auger filler is volumetric dosing. This means the machine dispenses a consistent volume of product rather than measuring its weight. The fill amount is determined by the number of rotations the auger screw completes. By precisely controlling the auger's revolutions, typically with a servo motor, the machine can repeatedly dispense the same volume of powder.

The operational cycle is simple yet effective:

- Bulk powder is loaded into the hopper.

- The auger motor is activated for a pre-set number of rotations or a specific duration.

- Simultaneously, the agitator stirs the powder to maintain a uniform density.

- The rotating auger draws the powder downwards and dispenses a specific volume through the funnel into the container.

- A cutoff mechanism stops the flow precisely to prevent drips or overfills.

For even higher accuracy, some advanced systems integrate a weigh-and-feedback system. In this setup, a scale checks the weight of each fill and sends feedback to the controller, which can then automatically adjust the auger's rotations for the next cycle to compensate for any variations in powder density.

Distinguishing Auger Fillers from Other Powder Food Packaging Machine Technologies

While auger fillers are incredibly versatile, they are not the only option for powder packaging. The best choice depends on the specific product and production needs. Here’s how they compare to other common technologies:

| Filling Technology | Primary Principle | Best Suited For | Key Advantages | Key Disadvantages |

|---|---|---|---|---|

| Auger Filler | Volumetric (by rotation) | Non-free-flowing and free-flowing powders (flour, protein powder, spices). | High versatility, excellent for dusty or sticky products, good balance of speed and cost. | Accuracy can be affected by changes in product density; complex to clean. |

| Volumetric Cup Filler | Volumetric (by cup size) | Free-flowing, granular products with consistent particle size (sugar, rice, beans). | High speed, simple to operate, lower cost, easy to maintain. | Less accurate than augers, not suitable for powders that compress or are non-free-flowing. |

| Net Weigh Filler | Gravimetric (by weight) | High-value, free-flowing products where exact weight is critical (gourmet coffee, snacks). | Extremely high accuracy, minimizes product giveaway. | Slower speeds, higher initial investment, sensitive to vibrations. |

| Vibratory Filler | Gravimetric (by weight) | Granules and pieces that are fragile or difficult to handle (nuts, coffee beans). | Gentle product handling, high accuracy. | Can be slower, generates more dust with fine powders. |

In summary, auger fillers occupy a sweet spot, offering unparalleled flexibility and control, especially for the challenging powders that other systems can't handle.

Key Features of a High-Performance Auger Powder Food Packaging Machine

Not all auger fillers are created equal. High-performance machines are distinguished by a set of key features that ensure they deliver on the promise of efficiency, accuracy, and safety. When evaluating an auger powder food packaging machine, these are the critical characteristics to look for.

Precision and Accuracy: The Hallmark of Auger Powder Food Packaging Machine

Precision is arguably the most critical feature of any filling machine. In the food industry, consistent accuracy is vital for adhering to regulations, ensuring product quality, and controlling costs. High-performance auger fillers achieve this through several advanced components:

- Servo Motor Drives: Modern auger fillers use servo motors instead of older clutch/brake systems to drive the auger. A servo motor is a closed-loop system that provides precise control over the auger's rotation, acceleration, and deceleration. Unlike a clutch motor, which runs continuously, a servo motor only runs when a fill is initiated and can be programmed for an exact number of rotations, down to a fraction of a degree. This leads to significantly higher fill accuracy and repeatability.

- Independent Agitator Control: The ability to control the agitator speed separately from the auger speed is crucial. This allows operators to optimize the powder conditioning for different product densities and flow characteristics without affecting the fill speed, further enhancing consistency.

- Feedback Systems: For ultimate precision, many machines feature a "fill-by-weight" system. An integrated scale weighs each filled container and sends the data back to the machine's control system. If a fill is slightly over or under the target weight, the controller automatically adjusts the auger revolutions for the subsequent cycles, ensuring an accuracy that can exceed 99.9%.

Versatility in Handling Diverse Powder Types for Food Packaging

The food industry packages an enormous variety of powders, each with unique properties. A key strength of the auger filler is its versatility in handling this diversity.

- Free-Flowing Powders: These are granular products like granulated sugar, salt, or instant coffee that flow easily. They require specific tooling, often a straight auger with a lip or cutoff to prevent dripping after the fill cycle ends.

- Non-Free-Flowing Powders: These are fine, sticky, or high-fat powders like flour, milk powder, cocoa, or baking mixes that tend to clump and bridge in the hopper. They require an auger with over-flights (a reverse spiral at the top) and a dedicated agitator to break up clumps and force the product down into the main auger flights.

- Interchangeable Tooling: High-performance machines are designed for quick and easy changeovers. Operators can swap out the auger and funnel tooling in minutes to accommodate different products and fill weights, minimizing downtime and maximizing production flexibility. This adaptability makes it possible to use a single machine for multiple product lines.

This versatility means that a single auger filler can be adapted for use in various packaging formats, from a semi-automatic station to a fully integrated Powder Doypack Packing Machine, which handles stand-up pouches.

Hygienic Design and Material for Food-Grade Auger Powder Food Packaging Machine

In food packaging, what the machine is made of and how it's designed are just as important as how it operates. Hygienic design is non-negotiable to prevent contamination and ensure food safety. Key principles include:

- Food-Grade Materials: All parts that come into contact with the product must be made from non-toxic, corrosion-resistant materials. Stainless steel (typically grades 304 or the more corrosion-resistant 316L) is the industry standard.

- Smooth Surfaces: Surfaces must be smooth, non-porous, and free of cracks, crevices, or sharp corners where product residue can accumulate and harbor bacteria. Welds should be ground and polished to a smooth finish.

- Ease of Cleaning: High-performance machines are designed for easy and thorough cleaning. This often includes features like a hinged or split hopper that can be opened for full access, and quick-disconnect clamps that allow for tool-less removal of the auger, funnel, and agitator. This modularity is essential for preventing cross-contamination between different product runs.

Advanced Automation and Control Systems in Modern Powder Food Packaging Machine

Modern auger fillers are no longer simple mechanical devices; they are sophisticated automated systems. Automation enhances efficiency, reduces the chance of human error, and provides valuable production data.

- PLC Control: The brain of the machine is the Programmable Logic Controller (PLC). The PLC coordinates all machine functions, from motor speeds to timing, ensuring every cycle is identical.

- HMI (Human-Machine Interface): Operators interact with the machine through a user-friendly color touchscreen HMI. From this interface, they can set fill parameters, store and recall product recipes for quick changeovers, monitor production in real-time, and access diagnostics for troubleshooting.

- Recipe Storage: The ability to save settings for different products and fill weights as "recipes" is a massive time-saver. Instead of manually re-calibrating the machine for each new run, an operator can simply select the appropriate recipe from the HMI, and the machine adjusts all parameters automatically.

- Data Acquisition: Advanced systems can collect and output production data, such as fill counts, average weights, and cycle times. This information is invaluable for quality control, inventory management, and overall equipment effectiveness (OEE) analysis.

These advanced control systems are what allow an auger filler to be the reliable core of a larger automated line, such as a high-speed Powder Rotary Packaging Machine, where precision and synchronization are paramount.

The Multifaceted Benefits of Integrating an Auger Powder Food Packaging Machine

Integrating an advanced auger powder food packaging machine into a production line delivers a powerful combination of efficiency, cost savings, and quality assurance. These benefits transform the packaging process from a potential bottleneck into a streamlined, value-adding operation.

Boosting Productivity and Efficiency with Auger Powder Food Packaging Machine

Automation is a direct driver of productivity, and auger fillers are designed to maximize output.

- Increased Speed: An automatic auger filler can achieve high fill rates, often reaching up to 60-90 cycles per minute or more, depending on the application and whether it's a single or twin-head model. This speed is a significant improvement over manual or semi-automatic methods, allowing businesses to meet high-volume production demands.

- Reduced Labor Costs: By automating the repetitive and precise task of filling, companies can reallocate their workforce to more value-added roles like quality control and machine supervision. A fully automated line requires minimal operator intervention.

- Minimal Downtime: Modern machines are built for reliability. Features like quick, tool-less changeover parts for different products and user-friendly HMIs for rapid setup drastically reduce the time between production runs. This efficiency is a core benefit, enhancing overall productivity.

Minimizing Waste and Maximizing Cost-Effectiveness with Powder Food Packaging Machine

In the food industry, every gram of product counts. Product "giveaway" from overfilling can erode profit margins, while underfilling can lead to regulatory issues and customer dissatisfaction. Auger fillers address this directly.

- High-Accuracy Dosing: Servo-driven augers can achieve fill accuracies of ±1% or better, and with integrated checkweighers and feedback loops, this can be improved to over 99.5% accuracy. This precision minimizes the risk of overfilling, saving significant amounts of product over thousands of cycles.

- Controlled, Clean Filling: The enclosed nature of the auger system and specialized funnel tooling helps to prevent dust and spillage during the dispensing process. This not only saves raw materials but also reduces the time and cost associated with cleaning the packaging area.

- Long-Term ROI: While the initial investment may be higher than manual methods, the long-term return on investment is substantial. The savings from reduced product waste, lower labor costs, and increased throughput make auger fillers a cost-effective solution for growing businesses.

Ensuring Product Integrity and Safety in Food Packaging Operations

Maintaining the quality and safety of the food product throughout the packaging process is paramount. Auger fillers are engineered with this as a top priority.

- Gentle Product Handling: The auger mechanism is designed to move powders gently, preventing degradation of sensitive products. This is particularly important for products where particle size and texture are key quality attributes.

- Hygienic Construction: As discussed, the use of food-grade stainless steel and a hygienic design that eliminates crevices and allows for easy, thorough cleaning is fundamental. This prevents microbiological growth and ensures the final product is free from contaminants.

- Reduced Contamination Risk: The enclosed filling system minimizes the product's exposure to the manufacturing environment. This is crucial for preventing airborne contaminants from compromising the product, a key requirement for meeting food safety standards like HACCP.

Seamless Integration with Existing Production Lines for Auger Powder Food Packaging Machine

A standout benefit of modern auger fillers is their modularity and ability to integrate into a complete packaging line. A filler is just one part of the process, and its ability to communicate and sync with upstream and downstream equipment is vital for a truly automated system.

- VFFS and HFFS Integration: Auger fillers are commonly mounted directly above Vertical Form Fill Seal (VFFS) or Horizontal Form Fill Seal (HFFS) machines. The filler works in sync with the bagger, dispensing the product at the precise moment to be captured in the newly formed pouch. This integration is essential for automated systems like the Powder Horizontal Packaging Machine.

- Pouch and Container Lines: They can also be integrated into lines with pre-made pouch machines or conveyors for filling rigid containers like jars and cans. Sensors and system logic ensure that a container is in place before a fill is initiated, preventing spills and keeping the line moving smoothly.

- Upstream and Downstream Connectivity: Advanced auger fillers can be connected with upstream equipment, such as screw conveyors that automatically feed powder into the hopper, and downstream equipment like checkweighers, metal detectors, capping machines, and labelers, creating a fully automated and hands-off packaging process.